Manufacturing Partnerships

GreenSeal® Technology

The advantages of bipolar batteries have been known for almost 100 years.

- Uniform current density

- Increased active material utilization

- Higher energy density

- Higher power density

- Simpler construction

However, practical concerns around the actual battery design and manufacturing process have prevented anyone from developing a commercially viable bipolar battery – until now. GreenSeal is a new technology that allows bipolar lead batteries to be used anywhere a large format battery is used today.

Licensing GreenSeal® Technology Makes a Battery Business Better

- Current licensees of GreenSeal® technology improve their business in multiple ways:

- Reduction in BOM can increase gross margins to 35% or greater

- Growth opportunities for existing business; regaining and preventing share that is going to lithium batteries

- New market opportunities to expand their reach enabled by higher performance at lower cost

- Future licensees of GreenSeal® technology boost their competitiveness and control their future:

- Against local and regional lead battery competitors

- Facing new technology entrants

- A path for new battery technology deployments in an advantageous platform

ABC provides active support through battery development:

- Advanced research, development, and analysis of active materials

- Engineering development of GreenSeal® battery designs and associated manufacturing processes

- Small-volume production line to run small lots

- Creates fieldable batteries with licensee active materials and other process specifications

Licensing GreenSeal® Technology Makes a Battery Business Better

- Improved profitability

- 30% bill of materials reduction

- 40% lower production capital costs

- Improved environmental stewardship

- 46% less lead content

- Path to zero emission plant

- Improved performance

- 35-50% more energy and power

- 2-3X longer cycle life – more possible

Advanced Battery Concepts

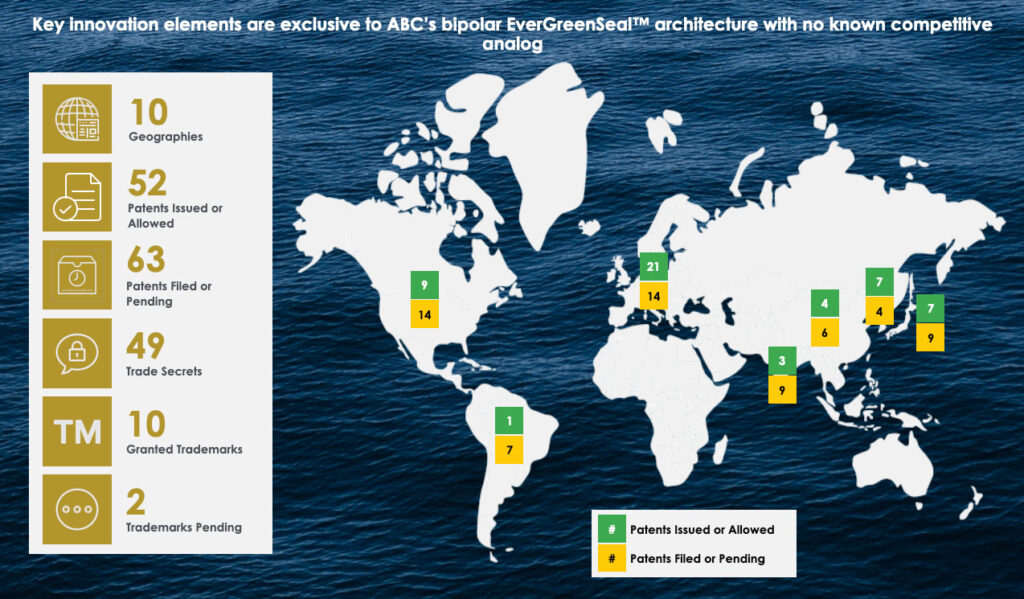

Intellectual Property

Advanced Battery Concepts

ABC has launched the GreenSeal Alliance

- ABC launched the GreenSeal® Alliance in 2019 to ready the lead battery suppliers for the change to bipolar battery production.

- Active participation with key material suppliers to ensure global supply availability.

- Active participation with key equipment makers to ensure global supply of high-volume manufacturing equipment.

- Many of these suppliers are well known in the industry and are ready to help XYZ move to scale manufacturing of GreenSeal® Technology.

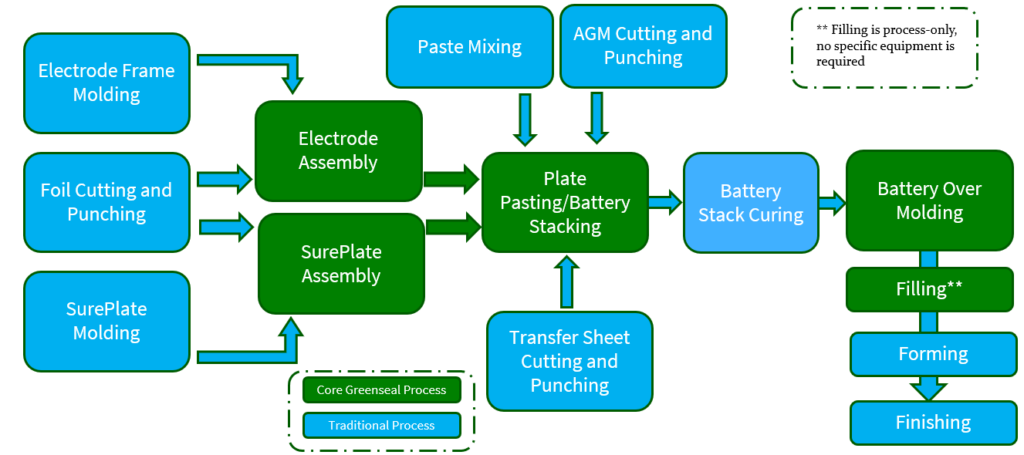

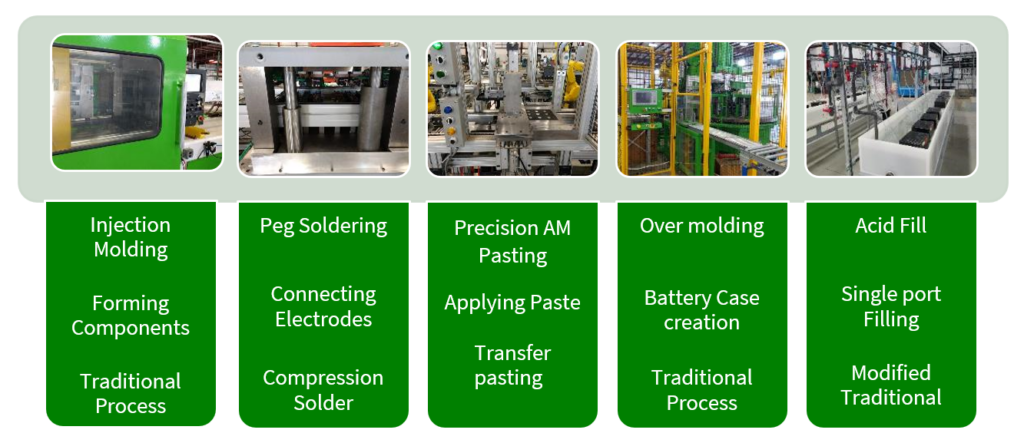

Greenseal Manufacturing Process Flow

Greenseal Core Processes

Production Line

- Designed to accommodate large batteries; up to 2.5kWh battery capacity

- Integrated modular system architecture designed to allow continuous flow or segregated operation of component assembly and pasting

- High level of automation and mechanization

- Critical to Quality measurements and error checking in line real time

- Low labor content – highly automized

- Core GreenSeal equipment compatible with existing factory infrastructure

- Precision AM pasting system adapts directly to existing paste mixing/feeding systems

- Handling of in-line raw materials based on traditional roll goods handling techniques

- Plastic components and current collectors may be supplied or manufactured in house

- Formation of GreenSeal adaptable to air or water formation methods

Other Key Benefits

- Greatly reduced power requirements

- Eliminates CAS molten pots

- Eliminates grid casting operations

- Reduces energy for formation

- No up draft fans

- Reduced Ah/kg-PAM (higher formation efficiency)

- Greatly reduces employee exposure to lead

- No paste offal

- No wash down required for pasting area

- No secondary wastewater treatment for paste waste needed

- No exposed cured/dried plates on inventory racks